Our Clean Energy Plant

Waste a Global Problem

Waste – a global problem faced by the civilised world.

• A global population that has passed 7 billion is creating an ever growing problem.

• Emerging economies are creating more waste as people aspire to the lifestyles of the West.

• By 2050, an estimated 9 billion people on the planet are expected to generate over 13,100 million tonnes of waste

– about 20% more than in 2009.

• The challenges we all face with waste have an impact on, and endanger, our wider environment.

• The traditional solutions of dumping or burning waste are no longer sustainable.

Waste An Opportunity

Waste can contain valuable resources.

• Argyll Energy is able to recover those valuable resources and utilise waste to produce “Green Energy”.

• The first Advanced Thermal Alambic Distillation facility is based in Sasolburg, South Africa.

• Argyll uses sources of waste tyres to feed its Sasolburg facility and will use waste tyres in its series of distillation plants in

South Africa with facilities in the UK and abroad planned for early 2016.

• Sasolburg processes the annual disposal of 4,200 tonnes of waste tyres.

• The facility is the flagship for the forthcoming Pretoria facility in South Africa and future facilities in the UK.

• Argyll Energy anticipates the Pretoria 120 tpd facility to produce “Green Energy – Green Electricity” by March 2016.

Why Tyres?

Used tyres are amongst the most visible and noxious global pollutants. Some 3 billion are produced annually and it is estimated that over 10 billion have been consigned to landfills.

Whilst Argyll Energy can process other types of waste, tyres in abundance are a readily available energy-rich resource when utilised for energy recovery.

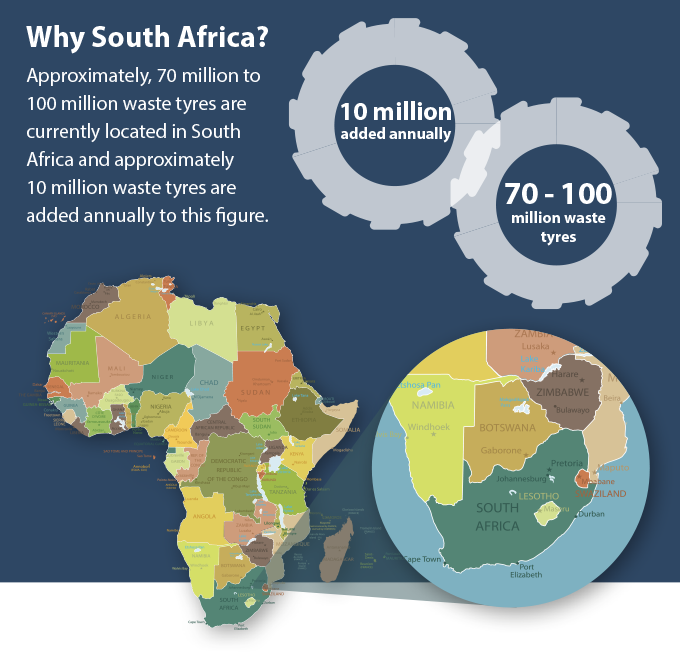

Why South Africa?

Approximately, 70 million to 100 million waste tyres are currently located in South Africa and approximately 10 million waste tyres are added annually to this figure.

Industrial Applications

• Energy storage systems

• Energy storage systems

• Heating

• Climatisation

• Cooling

• Sea water desalination

• Process heating

• Electrical power production

• Drying

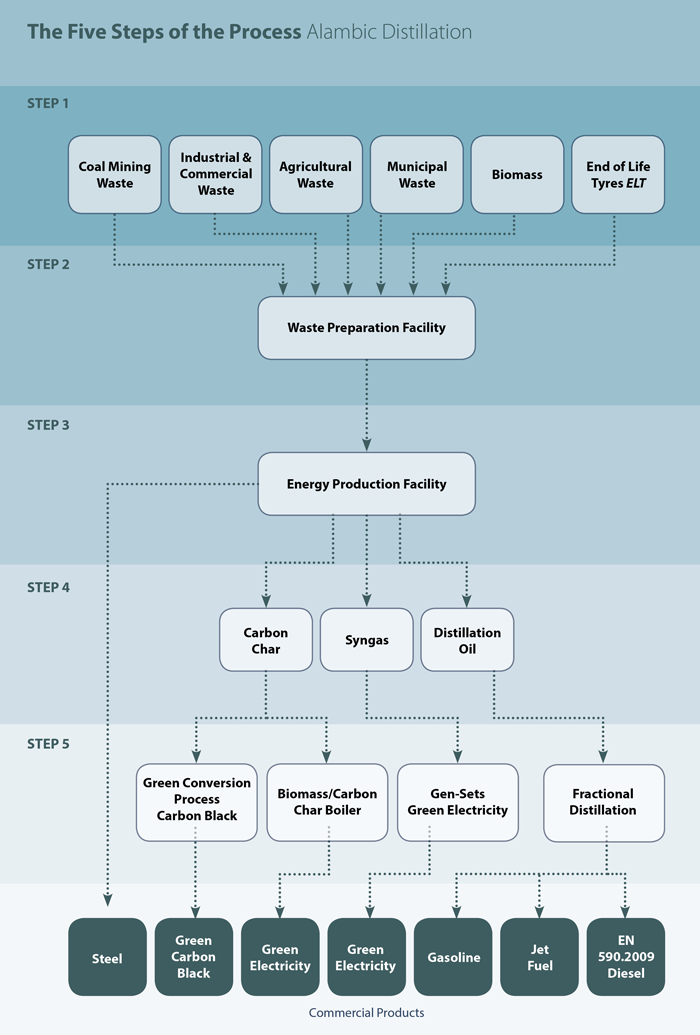

Distillation Process

• Steam

• Electricity

• Hot Water

• Cooling Energy

• Thermal Oil

• Carbon Black

• Bio Diesel & Bio Gas

Argyll Energy's Team

Argyll Energy’s team collectively brings over 150 years of experience in the energy and environmental areas of:

Argyll Energy’s team collectively brings over 150 years of experience in the energy and environmental areas of:

• Science • Technology • Research • Engineering Innovation • Business Development • Joint Ventures and Partnerships • Project Design, Management and Delivery

Energy Recovery Solutions

Whilst the distillation process is not new, Argyll Energy is now applying elements of the process in Energy Recovery from waste tyres and waste disposal.

Air Clean Technology

All of us share a common vision that the air we breath should be of the highest quality – free from harmful contamination and pollution. Argyll Energy aims to achieve this, by constant innovation and application of the most appropriate environmental technological solution.

Argyll Energy’s Solutions

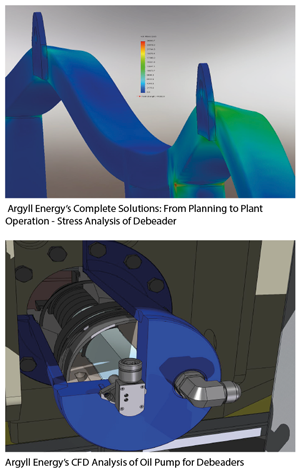

From Planning to Operation

• Engineering • Fabrication • Erection • Commissioning • After Sales Service • Remote Maintenance • Plant Operation • Energy Production Argyll Energy is one of the leading companies in the world to create electricity and bio-fuels with zero-carbon emissions from all types of waste: • Tyres • Plastics • Commercial Waste • Industrial Waste • Household Waste • Hospital Waste • Peat • Coal Fines

The World – Current and Future Operations

Currently, discussions on Argyll Energy’s Advanced Thermal Distillation Process are taking place in: • Scotland • England • Middle-East • Africa • USA • Australia A further 85 countries are considering Argyll Energy’s processes including: • Utilisation of fossil based fuels more cleanly and efficiently, • Landfill elimination and • Waste as a valuable resource The aim being to significantly reduce their CO2 profile and save the planet for our children.

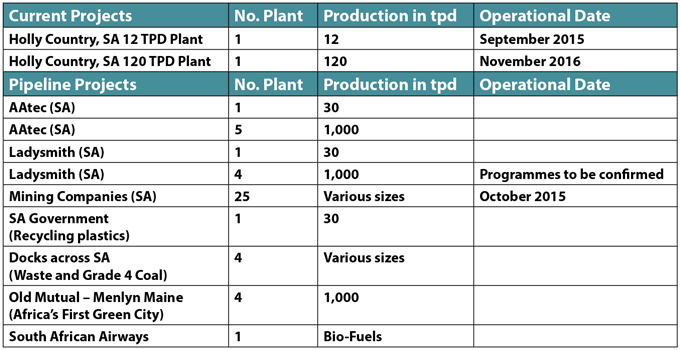

Current Projects No. Plant Production in tpd Operational Date Holly Country, SA 1 12 June 2015 Pretoria West – City of Tshwane, SA 1 120 Nov 2015 Pipeline Projects No. Plant Production in tpd Operational Date Pretoria West – City of Tshwane 1 1,000 AAtec (SA) 1 30 AAtec (SA) 5 1,000 Ladysmith (SA) 1 30 Ladysmith (SA) 4 1,000 Programmes to be confirmed Mining Companies (SA) 25 Various sizes early 2015 SA Government (Recycling plastics) 1 30 Docks across SA (Waste and Grade 4 Coal) 4 Various sizes Old Mutual – Menlyn Maine (Africa’s First Green City) 4 1,000 South African Airways 1 Bio-Fuels

Typical Feasibility Study of Waste to Energy Projects

Argyll Energy’s Advanced Thermal Alambic Distillation Facility in Holly Country, South Africa

The feasibility study considers: 1. Project description and pre-qualification 2. Feedstock agreement (initial LOI and MOU) a) Define feedstock, including laboratory analysis. b) Plant target capacity, tonnes per day. c) Tipping Fees, gate price or cost per tonne. d) Evaluate feedstock source, including company history, underlying contracts, guarantee of term commitment. e) Define feedstock agreement terms and conditions (minimum number of years). f) MOU, LOI, Term sheets, or option for feedstock with major points committed. 3. Site location a) MOU or option on site location with terms and conditions. b) Identify existing and required infrastructure, including access to major roads, substations and transmissions lines, fuel tanks, water lines. Gas lines, rail spurs, waterways, as well as proximity to major industry that could purchase electricity or fuel. Proximity to refineries, and possible problematic site issues to be addressed. c) Identify all relevant stakeholders. d) Initial environmental site feasibility and assessment. e) Prepare site assessment report, including government agencies having jurisdiction over all site permits.

4. Off-take agreements a) MOU or LOI with specifications, price adjustment formula, terms and conditions. • Synthetic oil or refined products • Gas • Electricity • Carbon char or refined carbon black • Steel (if ELT are feedstock) 5. Preliminary engineering design a) Estimated costs for facility. 6. Project development timeline 7. Renewable credits assessment report a) Carbon credits. b) Funding. 8. Pro-forma financials 9. Business plan for project financing 10. Submission of feasibility report for consideration and financing.

Services and Technologies

Facilities and Laboratories

Argyll Energy will successfully deliver its services, facilities and products to all clients and partners by optimising the use of all resources through strict project management control procedures.

Services and Technologies

Contract Research & Development:

Environmental solutions, waste management, automotive, industrial and buildings information. Technology Consultancy. Thermofluids. Aerodynamics. Pollution, emissions and monitoring, Technology Transfer, CPD and specialist training programmes. IT Technologies: Computational Fluid Dynamics (CFD software). Computer Aided Engineering (CAE/FEA). Software development. Computer integrated manufacturing. Supply of engineering personnel. Sensor Technologies: Emissions monitoring. Manufacturing: Concurrent and component engineering. Advanced Engineering and prototype manufacture. Emissions: Emissions measurement. Facilities and Laboratories Energy Production from Waste Facilities. Laboratories: Emissions, fuels and specialist. IT Facilities: CAD, FEA and CFD.

Argyll Energy’s Distillation Facilities

Customised stationary and mobile systems for different kinds of waste • Capacity 6000 to 1,000,000 kg per day • Solid, paste like, liquid and gaseous fuels • Calorific value range 0 to 55 MJ/kg

Worldwide Your Reliable Partner

Argyll Energy believes in striving for excellence in client partnerships and forming networks worldwide for mutual benefit. This partnership strategy enables Argyll Energy to remain responsive to current demands, invest in the future of the industry and support the enhancement of our services to clients.  We truly believe that our growth can only be achieved through building and maintaining profitable partnerships with our clients. Argyll Energy aims to build futures. • AAA Engineering CA • Aker Solutions NO • Eenhoorn Sustained Effect NL • MBDA FR • Siemens DE • Scogen IN • Untha AU • Tong Peal UK • Xingxiang Huayin Renewable Energy CN • Redisa ZA • Eskom ZA • ArcelorMittal ZA • Old Mutal ZA • GCX South Africa • Exxaro

We truly believe that our growth can only be achieved through building and maintaining profitable partnerships with our clients. Argyll Energy aims to build futures. • AAA Engineering CA • Aker Solutions NO • Eenhoorn Sustained Effect NL • MBDA FR • Siemens DE • Scogen IN • Untha AU • Tong Peal UK • Xingxiang Huayin Renewable Energy CN • Redisa ZA • Eskom ZA • ArcelorMittal ZA • Old Mutal ZA • GCX South Africa • Exxaro

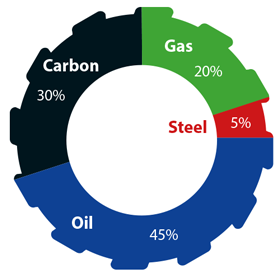

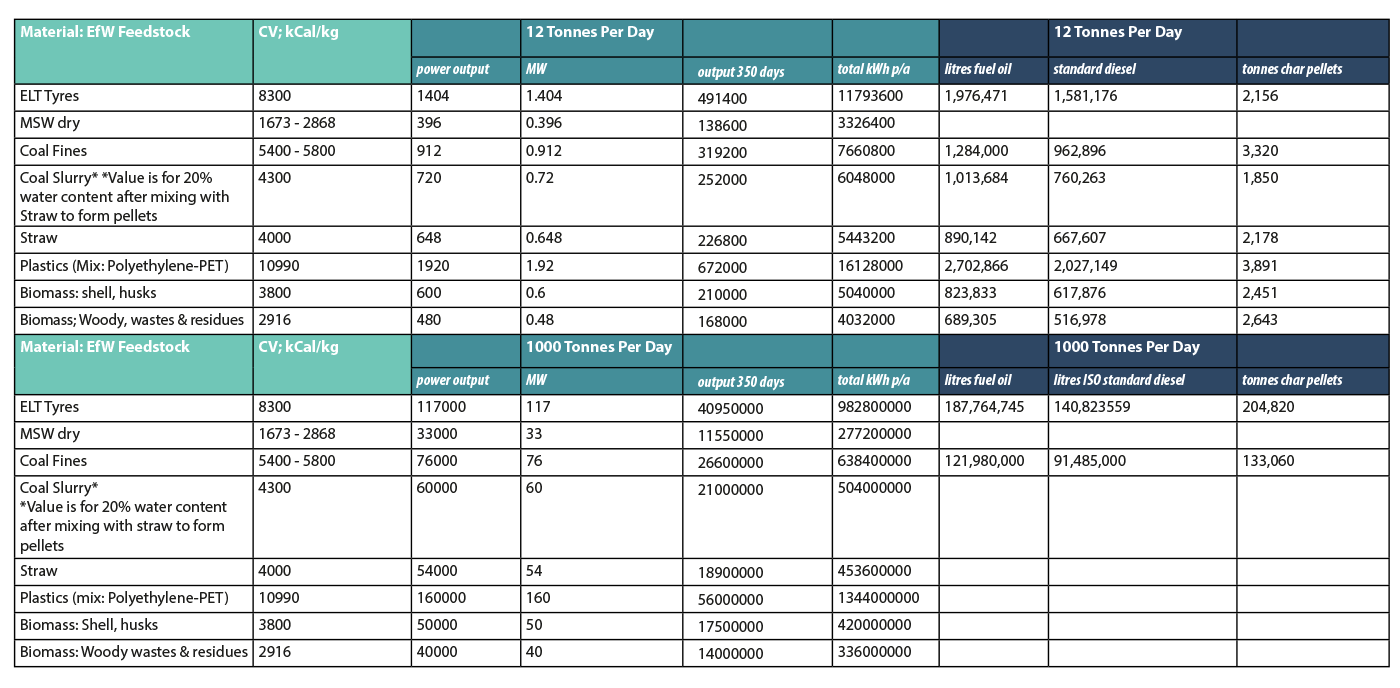

EFW Performance Data

Data is based on average of feedstock